Services & Refurbishment

JDA Retro Services are the authorised service centre for Webercarburettor.com

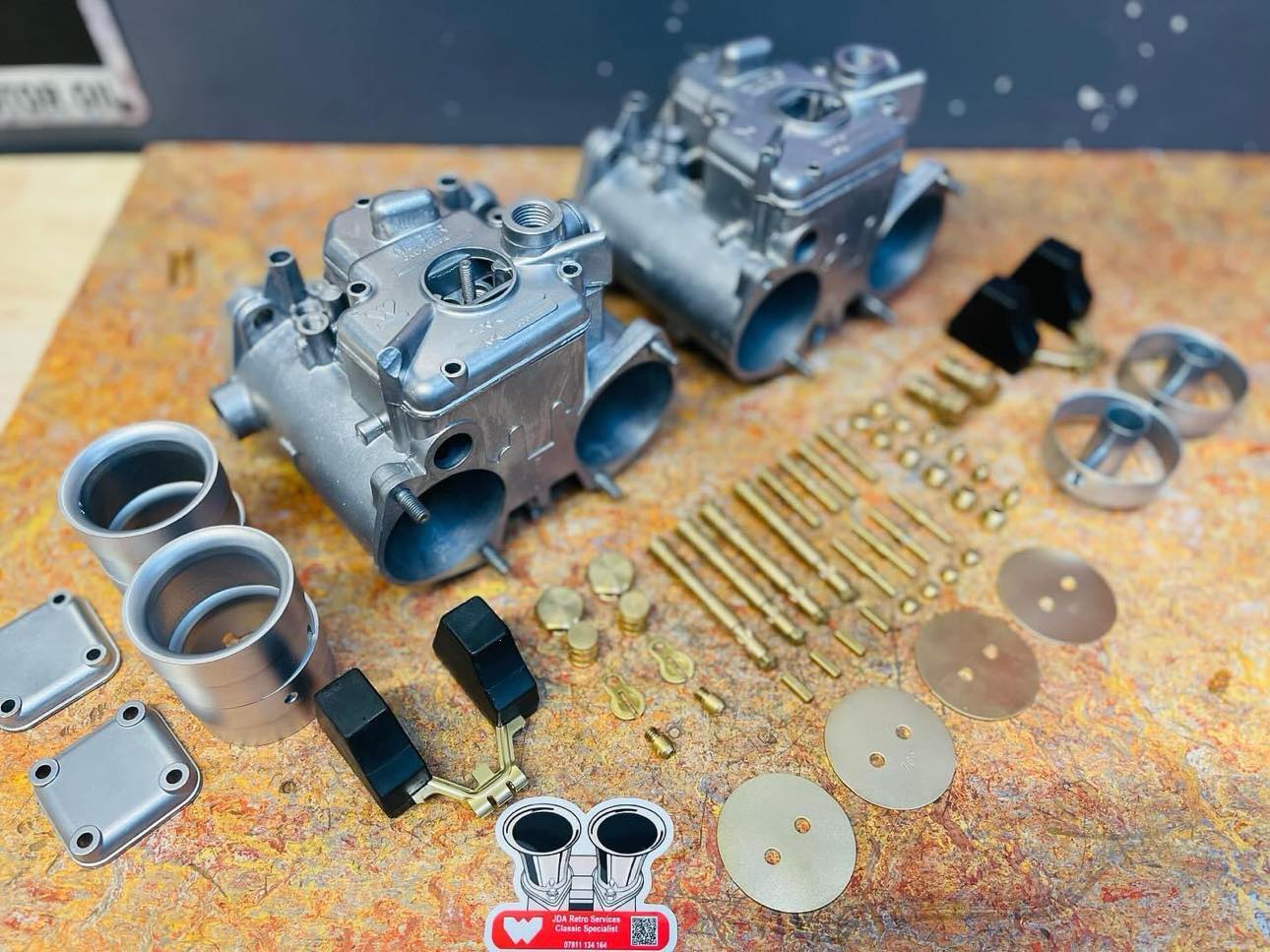

JDA Retro Services offer component and carburettor refurbishment primarily for Weber and Dellorto carburettors.

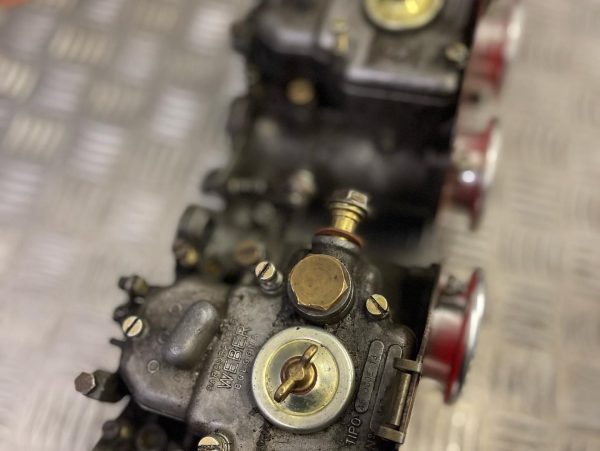

Being carburettor specialist, we can assess, refurbish and bring your carburettor back to as new condition.

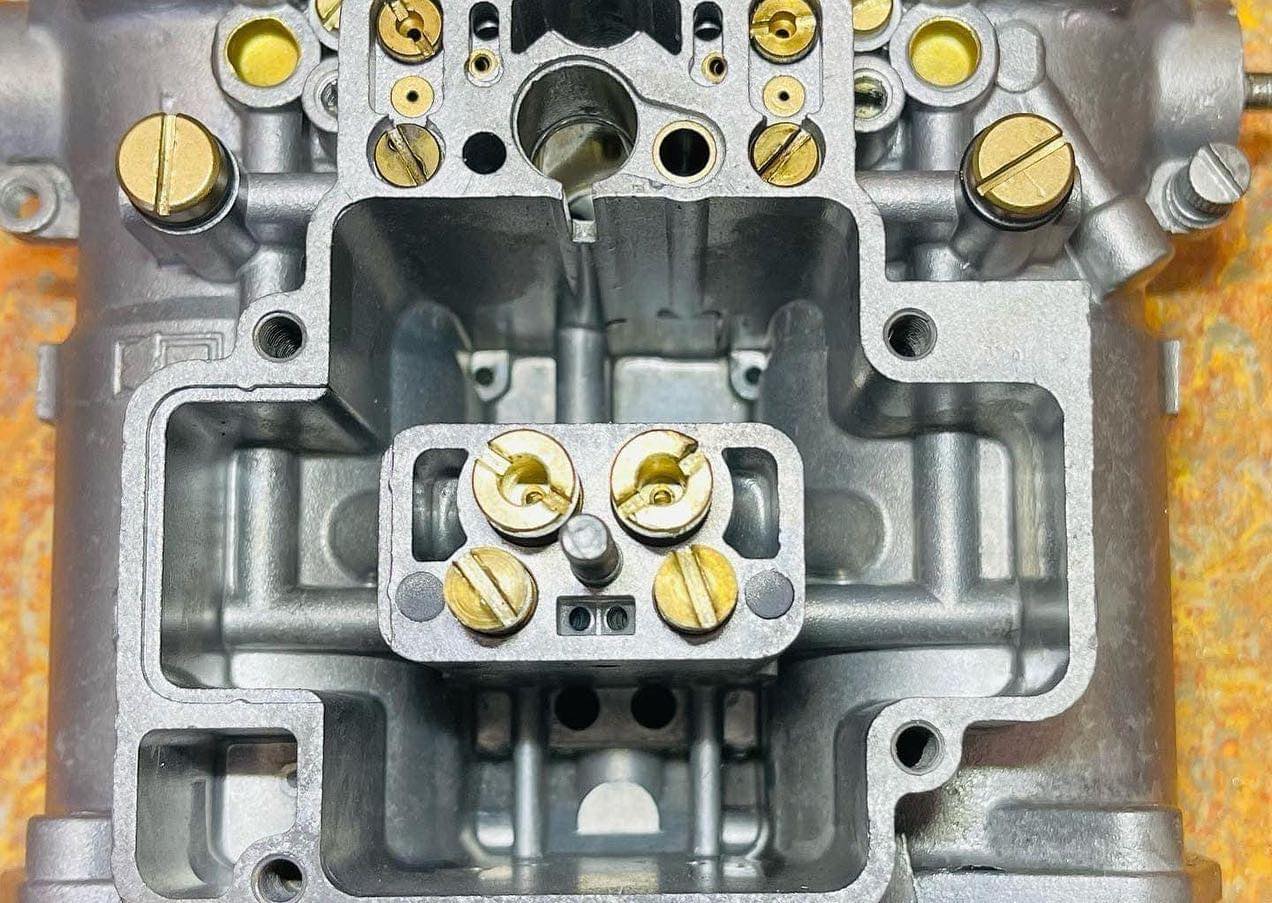

All carburettors are cleaned externally and internally.

All oxidisation and contaminates are removed using our 3 stage cleaning process developed specifically for carburettors which is non destructive to the carburettor body or components.

WE DON’T JUST CLEAN THE OUTSIDE OF CARBURETTORS

Each carburettor is inspected and a condition report provided to the customer.

The carburettors are then re-assembled using our bespoke service kits, our Weber service kit designed by JDA for example uses Genuine Weber components and has over 60 parts compared to the standard off the shelf service kit with just over 20 parts.

We then subject each finished carburettor to fuel pressure and leak testing along with balance testing.

This is carried out either on our custom engine test stand or by bench testing using specialist equipment.

Photos and videos are made available to customers throughout the process.

Our clients

JDA Retro Services are used by both UK based and international customers.

Our client base includes professional engine builders, historic race and rally teams, classic vehicle restorers and classic vehicle owner/enthusiast.

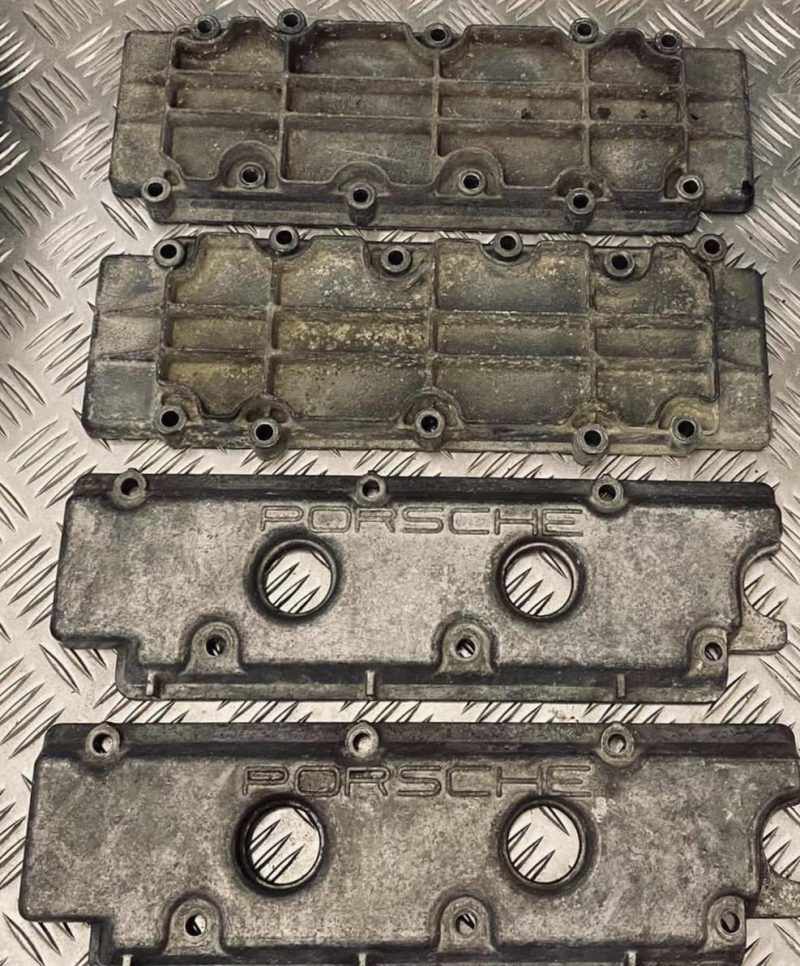

With customers and owners around the world intrusting us with their precious carburettors from Lotus, Ferrari, Aston Martin, Lancia, Alfa Romeo, Ford, Vauxhall, Sunbeam, Toyota and many many more you can be confident your carburettors are in the best possible hands.

Client list includes, but not limited to:

- Classic Team Lotus

- Jon Wood Race Engines

- Evans Power

- Toovey Race Engines

- RD Engineering NZ

- Mallock Sports

Team Leo’s Motorsport

- Brayon Classic Engineering

- Fulvia Classics

- Rallye Sport UK

- Redhill Motorsport

- Carrs Ferrari

MK14 Components

Before & After Gallery

Other processes

In addition to carburettors JDA offers the following specialist cleaning and refurb processes for carburettors and vehicle components along with carrying out batch processing for engineered parts that require consistent high standard finishing.

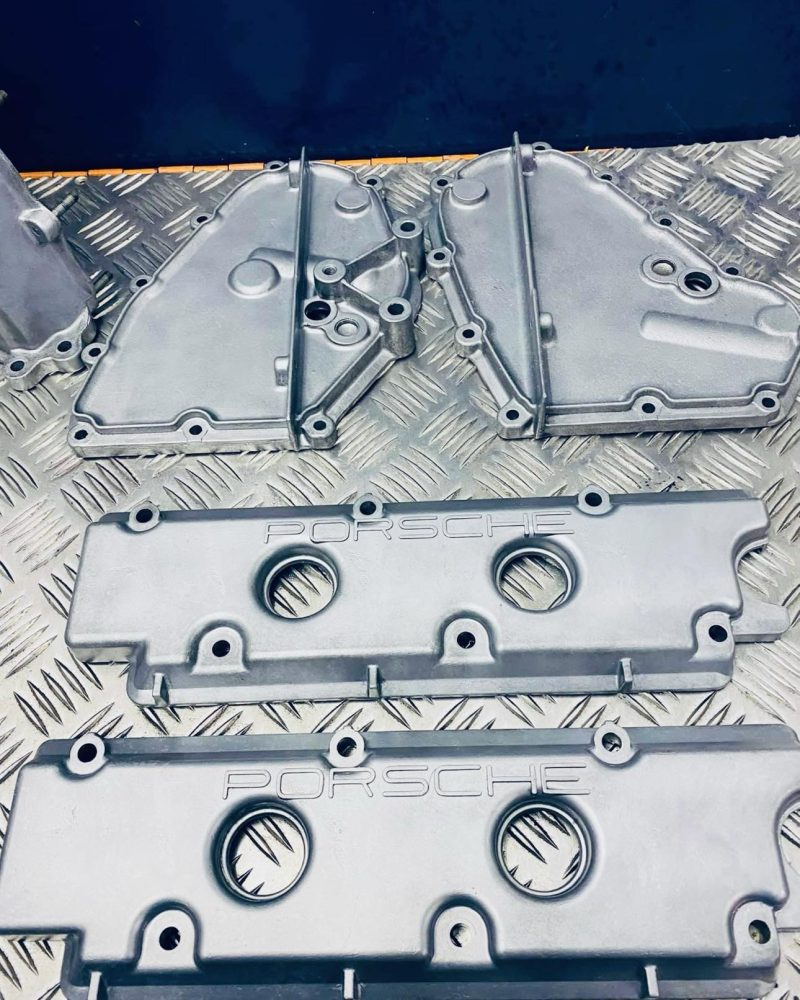

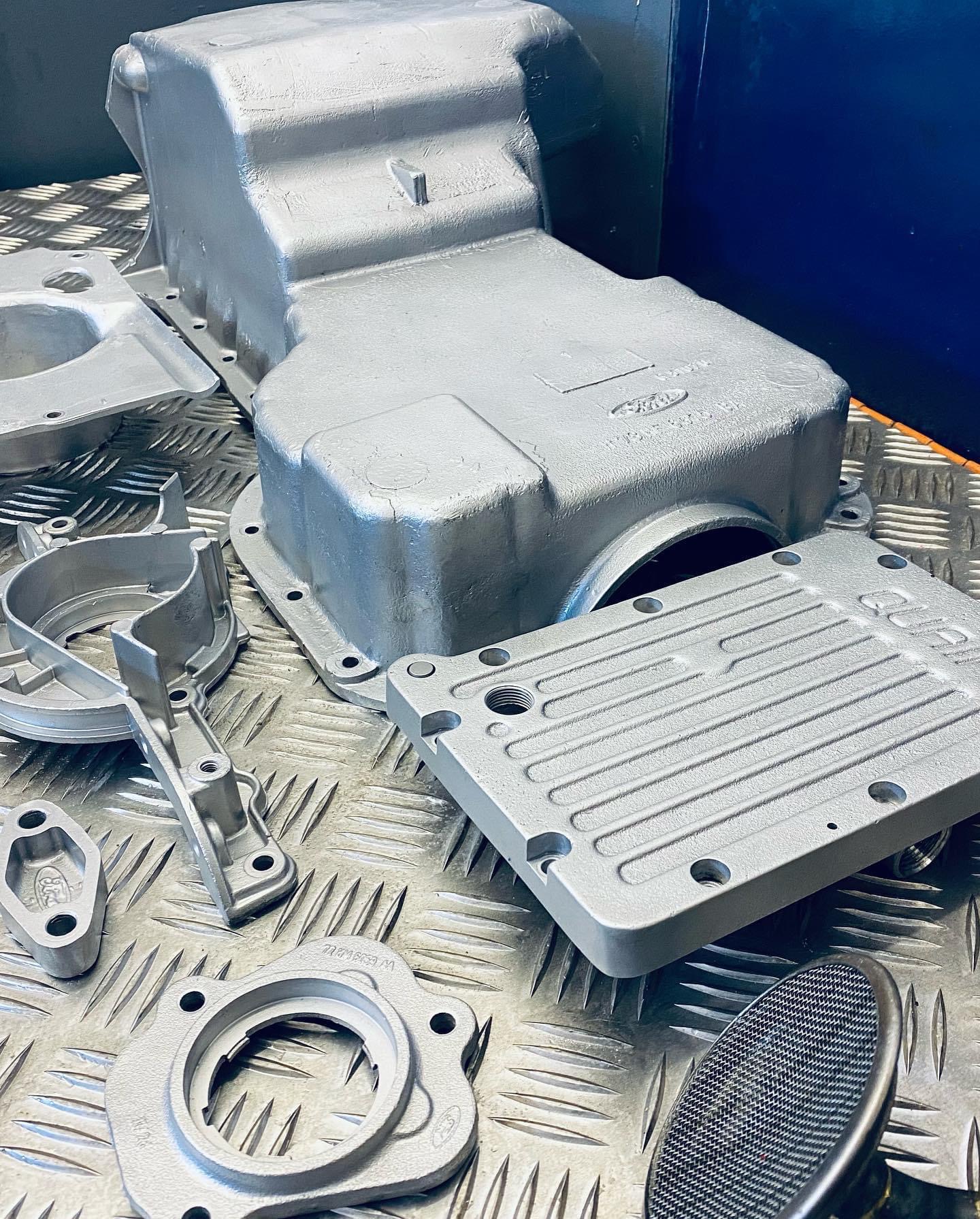

VAPOUR BLASTING

Primarily for aluminium components and carburettors vapour blasting is a non aggressive media cleaning process using a specialist wet media cabinet.

We used pressurised water and glass beads to remove years of oxidisation contaminates and debris.

This process not only cleans the item but leaves an as new satin polish finish.

Excellent for aluminium vehicle parts motorbike casings manifolds engine components and carburettors.

ULTRASONIC CLEANING

This process uses ultrasonic frequency and the appropriate cleaning agent to remove deposits and ingrained contaminants.

Excellent for carburettors and other intricate components.

There is no abrasive media in this process.

Recommended as a pre and final process when vapour blasting carburettors.

DRY MEDIA BLASTING

Our pressure pot system is a more aggressive media blasting process to remove rust corrosion contaminates and previous paint and powder coated finishes.

An excellent process to prepare components by not only cleaning the substrate but leaving an etched key for painting or powder coating.

CHEMICAL HOT PARTS WASH

Using non corrosive cleaning agents to prepare heavily soiled parts prior to media blasting.

Service & Refurb Enquiries

For pricing and enquiries, please use the contact form or give us a call on 07811 134164 to discuss your requirements.

Carburettor servicing terms and conditions

All carburettor sent in for servicing must be accompanied with the signed terms and conditions and customer details form.